- Suction process:

The inlet side of the screw inspiratory mouth, must be designed to make the compression chamber can inhale fully, and screw air compressor and air intake and exhaust valve group, inlet opened and closed by a regulator of the adjustment, as the rotor turns, main rotor tooth groove space when transferred to the inlet end wall openings, its space Z is big, the rotor tooth groove space and liberty in the inlet air are interlinked, Because the air in the exhaust groove is fully discharged, exhaust at the end of the groove is in a vacuum state, when turned to the air inlet, the outside air is sucked, along the axial flow into the main and deputy rotor groove. Screw air compressor maintenance reminds that when the air is full of the whole groove, the inlet side face of the rotor turns away from the air inlet of the housing, and the air between the groove is closed.

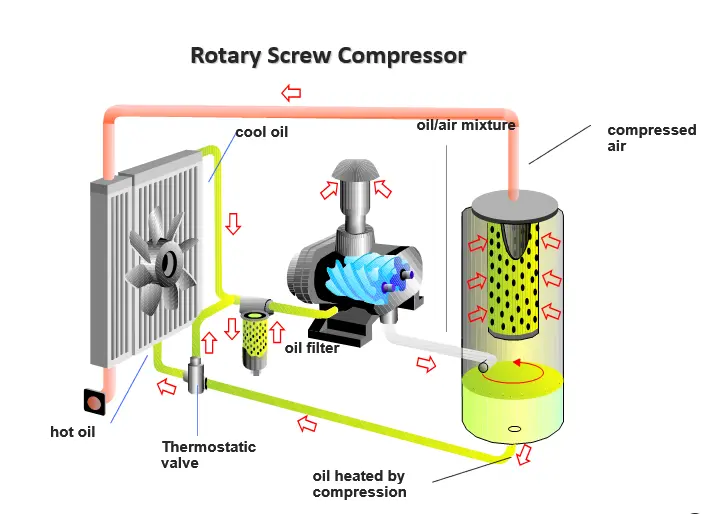

- Compression and oil injection process:

In the conveying process, the meshing surface gradually moves to the exhaust end, that is, the tooth groove between the meshing surface and the exhaust port gradually decreases, the gas in the tooth groove is gradually compressed, the pressure increases, this is [compression process]. At the same time, the lubricating oil is sprayed into the compression chamber and mixed with the chamber gas because of the pressure difference.

- Sealing and conveying process:

At the end of the suction of the main and secondary rotors, the tooth summit of the main and secondary rotors and the casing are closed, and the air in the tooth groove is closed and no longer flows out, that is, the sealing process. The two rotors continue to rotate, its peak and groove in the suction end anastomosis, anastomosis surface gradually moved to the exhaust end.

- Exhaust process:

When the rotor in the screw air compressor maintenance meshing face to with casing exhaust, (high pressure of the compressed gas Z) of the compressed air to escape to until the teeth with tooth groove of the mating surface to the exhaust end face, the two rotor mating surface and the tooth groove casing vent space is zero, that is complete (exhaust process), At the same time, the length of the tooth groove between the meshing surface of the rotor and the air inlet of the housing reaches Z length, and the suction process is going on again.